The Rise of Japanese Denim: What Makes It So Special?

Moische.com

Japanese denim has gained a reputation for its exceptional quality, craftsmanship, and unique characteristics. This article explores what sets Japanese denim apart and why it has become a favorite among denim enthusiasts worldwide.

Superior Craftsmanship

Japanese denim is renowned for its meticulous craftsmanship. Artisans in Japan use traditional techniques combined with modern technology to create denim that is both durable and aesthetically pleasing. The attention to detail in every step of the production process ensures a high-quality product.

Premium Materials

One of the key factors that make Japanese denim special is the use of premium materials. Japanese mills often use high-quality, long-staple cotton, which results in a softer, stronger fabric. This premium cotton is typically sourced from regions known for producing top-grade fibers.

Selvage Denim

Japanese denim is often associated with selvage (or selvedge) denim, characterized by the tightly woven band on the fabric's edge. This type of denim is produced on old shuttle looms, which weave the fabric at a slower pace, creating a denser, more durable textile. Selvage denim is known for its clean finish and resistance to unraveling.

Unique Dyeing Techniques

Japanese denim producers are known for their innovative dyeing techniques. Many use natural indigo dye, which creates rich, deep colors that fade beautifully over time. The dyeing process is often done by hand, with multiple dips to achieve the desired hue and intensity, resulting in a unique and vibrant denim.

Attention to Detail

The meticulous attention to detail extends to every aspect of Japanese denim, from the stitching to the hardware. The stitching is typically done with high-quality thread, ensuring durability and a polished look. Rivets, buttons, and other hardware are carefully selected to complement the overall design and enhance the garment's longevity.

Cultural Influence

The Japanese approach to denim is deeply influenced by the country’s culture of precision and perfectionism. This cultural emphasis on quality and artistry is evident in every pair of Japanese jeans, making them a highly sought-after product in the global market.

Stay ahead in denim fashion with insights into the latest innovations and trends. From sustainable practices and eco-friendly materials to smart fabrics and customization options, explore how technology and creativity are shaping the future of denim. Learn about new denim styles and production techniques that promise to revolutionize your wardrobe.

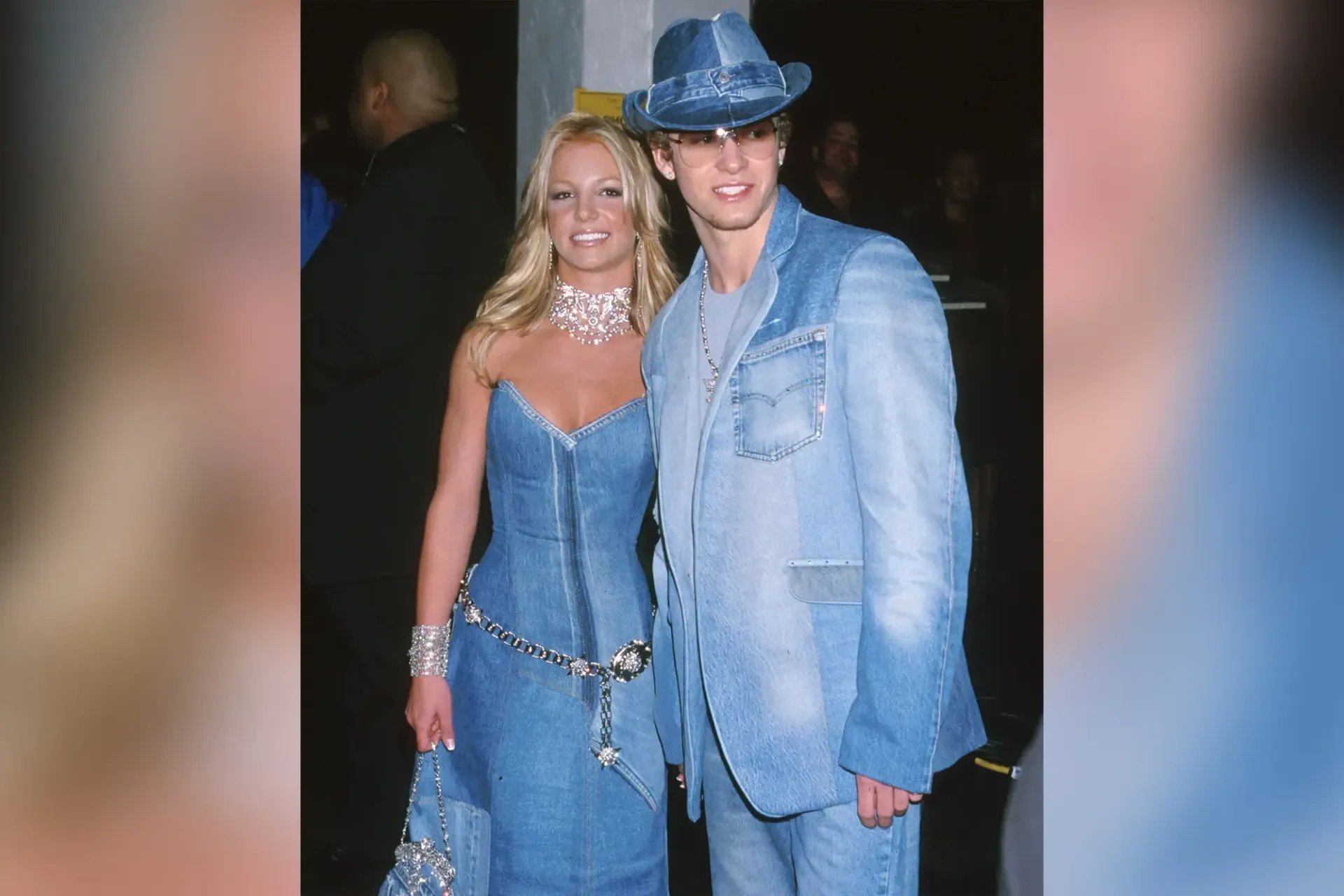

Discover the world of denim accessories that go beyond jeans and jackets. From stylish bags and hats to chic shoes and belts, explore how denim is used to create unique and fashionable accessories. Learn how to incorporate these pieces into your wardrobe for a fresh and trendy look that showcases the versatility of this timeless fabric.

Unleash your creativity by customizing your jeans with these DIY tips and tricks. Learn how to add unique details like distressing, embroidery, patches, and more to create one-of-a-kind denim pieces. Whether you want a subtle change or a bold transformation, our guide will help you personalize your jeans to reflect your style and personality.

Explore the detailed process of denim production, from cotton harvesting and yarn dyeing to weaving, cutting, and sewing. Learn about the various steps involved in creating your favorite pair of jeans, including fabric finishing techniques and quality control measures. Understand the craftsmanship and technology that go into making durable and stylish denim garments.

Discover how denim has shaped and been shaped by pop culture. From James Dean's rebellious style to Madonna's fashion statements, learn about the iconic moments and figures that made denim a cultural staple. Explore how music, movies, and celebrities have influenced denim trends, turning this fabric into a symbol of individuality and timeless style.

Embrace the return of vintage denim with our guide on how to find and style retro jeans. Learn where to shop for authentic vintage pieces and discover tips on styling them to fit modern trends. From high-waisted cuts to flared legs, explore how to incorporate timeless denim styles into your wardrobe for a unique and fashionable look.

Understand the different denim fits to find your perfect pair of jeans. From slim and straight to skinny and beyond, learn the key characteristics of each fit, including how they taper and where they sit on the waist. Discover styling tips for each type to ensure you look and feel great in your denim, no matter the occasion.

Dive into the world of denim fabrics and learn about the differences between raw and selvage denim. Discover the unique qualities of each type, including their durability, aging process, and distinctive features. Understand how these fabrics are made and what sets them apart, helping you make informed choices when selecting your next pair of jeans.

Dive into the world of denim fabrics and learn about the differences between raw and selvage denim. Discover the unique qualities of each type, including their durability, aging process, and distinctive features. Understand how these fabrics are made and what sets them apart, helping you make informed choices when selecting your next pair of jeans.